bend-strength-test-machine|guided bend tests : maker ADMET bend testing machines accurately and reliably measure the flexural properties of metals, concrete, plastics, medical devices, and more. monday.com foi visitado por mais de 100 mil usuários no último mês

{plog:ftitle_list}

WEB2 dias atrás · Podrobné a spolehlivé předpovědi počasí od meteorologů , radarové snímky, dlouhodobá předpověď počasí na 14 dní, teplotní a srážkové mapy, zpravodajství, bouřky

ADMET bend testing machines accurately and reliably measure the flexural properties of metals, concrete, plastics, medical devices, and more.Universal testing machines equipped with bend fixtures are used to calculate .Bend testing (also flex or flexural testing) is commonly performed to measure the .Bend test machines are typically universal testing machines specifically configured to evaluate material ductility, bend strength, fracture strength, and resistance to fracture. Bend tests tend to be associated with ductile metals .

The bend test is a fundamental and versatile materials testing method used to assess the ductility, flexibility, and strength of a material. The test provides insights into a material's toughness and ability to resist deformation under .Bend Testing: Evaluation of Strength and Ductility of Materials. The bending test is one of the main mechanical tests used in engineering and materials science to evaluate the flexural .Sawyer’s 25 Ton Bend and Tensile Tester. Model 273-25. For weld certification and qualification, Sawyer’s line of weld inspection and tensile testing equipment is hard to beat, and the 25 Ton Guided Bend and Tensile Tester is no .Typical graph showing strength test: Typical graph showing 3-point bend strength test: Typical graph showing 4-point bend strength test: We provide force measurement instruments and materials testing machines for flexural .

Or, it may involve bending a material until the material experiences a break and determining both the load and deflection required to initiative the break limit. Typical graph showing 3-point bend strength test: We provide force measurement instruments and materials testing machines for bending tests such as 3-point and 4-point bend.

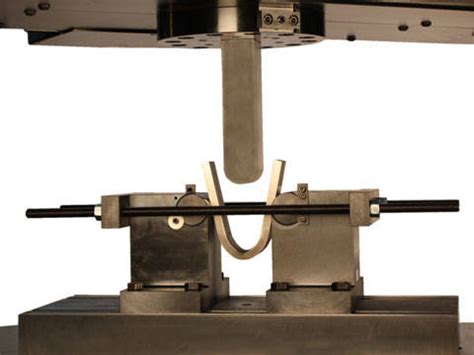

Single-edge notch-bending specimen (also called three-point bending specimen) for fracture toughness testing.. The fracture toughness of a specimen can also be determined using a three-point flexural test. The stress intensity factor at the crack tip of a single edge notch bending specimen is [3] = [() / / + / / + /] where is the applied load, is the thickness of the specimen, is .Fig.1(a) shows a guided bend test jig that uses a male and a female former, the commonest form of equipment Fig.1(b) shows a wrap-around guided bend test machine that works on the same principles as a plumber's pipe bender. The strain applied to the specimen depends on the diameter of the former around which the coupon is bent and this is related to the thickness of .Test results include flexural strength and flexural modulus. Brittle Materials. When a 3-point bend test is done on a brittle material like ceramic or concrete, flexural strength is often called modulus of rupture (MOR). This test provides flex strength data only, not stiffness (modulus). The 4-point test can also be used on brittle materials .The types of bend tests discussed are bending ductility tests, bending strength tests (ASTM E 855), bend tests as per EN 12384 and JIS 3130, and computer-aided bending tests. The three standard bending strength tests are the cantilever beam bend test, the three-point bend test, and the four-point bend test.

pinpoint moisture meter

A bend test, also known as the flexural test, is a standardized method employed to assess the ductility, bend strength, fracture strength, and resistance to fracture of materials.This testing methodology involves subjecting a specimen to a controlled bending force to evaluate its resistance to deformation. The bend test is important in construction processes involving .

While it is easy to imagine why bend testing needs to be performed on rigid materials like plastics (ASTM D790) and concrete (ASTM C1609), in reality bend test applications are common in a variety of industries. Universal testing machines equipped with bend fixtures are used to calculate flexural modulus, flexural strength, yield point, and more.Instron manufactures tensile, compression, fatigue, impact, rheology, and structural testing machines, testing a variety of materials and range of applications. Telephone: +1 800 877 6674 Small-scale bending tests (Fig. 7) provide a simply fixable set-up for anchors characterization in combined shear-bending and even in equilibrium critical application.It is probably the closest combination of stresses to simulate a real-scale bended structure, which is possible through a small-scale test [97].In this case, recovery of characterization data from the .Bend testing (also flex or flexural testing) is commonly performed to measure the flexural strength and modulus of all types of materials and products. This test is performed on a universal testing machine (tensile testing machine or tensile tester) with a 3 point or 4 point bend fixture. The key analysis when performing bend testing are:

TestResources manufactures and supplies universal test machines, tensile testers, dynamic testing machines, and much more. Call us today (800)430-6536. . and modulus involves analyzing the peak stress and strain experienced by the test specimen during the three-point bending flexural test. Flexural strength is determined based on the maximum .

Find your bending testing machine easily amongst the 447 products from the leading brands (A&D Company, Haida, Instron, .) on DirectIndustry, the industry specialist for your professional purchases. . AC220V 10A or specified by user Glass3-points bending test Glass4-points bending test Glass compressive strength test Metal/sheet tensile .Elastic modulus in bending (i.e., flexural modulus), stress-strain behavior, and failure limits in bending all can be obtained using the simple sample geometry of a 3-point bend test. ASTM D790 or ISO 178 covers flexural properties for .Purpose: Bend testing is typically a qualitative test used to evaluate a material’s ductility, toughness, or brittleness. It’s often employed in quality control to ensure that materials or products meet specific bendability criteria. Methodology: .

Test results include flexural strength and flexural modulus. Brittle Materials. When a 3-point bend test is done on a brittle material like ceramic or concrete, flexural strength is often called modulus of rupture (MOR). This test provides .Our compact bench-top universal testing machines (UTMs), available in 0.5 kN, 1 kN, and 2.5 kN single-column models, are ideal for tensile and compression testing of various materials, products, and components. Powered by the intuitive VectorPro™ software, these portable UTMs (weighing under 30kg) offer powerful performance in minimal bench space. The 2.5 kN model .

EN1288-3 gives a schematic description of the test setup for the four point bending test (Fig. 1). This description is a vastly simplified version of the actual testing equipment used in most industrial applications and labs. Therefore, it can be interpreted in different ways resulting in different values for k e from theoretical calculations .Find here Bend Test Equipment, Bend Testing Machine manufacturers, suppliers & exporters in India. . Industrial Mild Steel Flexural Strength Testing Machine, Capacity: 100kg / 3000kg, 220v Ac 50 Hz ₹ 3.40 Lakh. Texcare Instruments. Contact Supplier. Bending Tester For Conduits, For Laboratory, Instrument Type: Manual

The 3-point bend tests specified in ISO 178 and ASTM D790, describe classic standardized characterization methods for rigid and semi-rigid plastics.The flexural properties determined with these tests are of great importance to designers, engineers and manufacturers to ensure that the plastic material used meets the requirements for its intended application.Materials characterization of bending and flexing properties, including flexural modulus and flexural strength. Learn more.The bending test or bending tensile test is a proven test method when it comes to the destructive testing of materials. Various types of bending tests are common in practice. They mainly differ in the sample storage and the number of load introductions. The resulting results are the bending force, deflection and stress-strain value of the material specimens.

The four-point flexural test provides values for the modulus of elasticity in bending, flexural stress, flexural strain and the flexural stress-strain response of the material. This test is very similar to the three-point bending flexural test.The major difference being that with the addition of a fourth bearing the portion of the beam between the two loading points is put under maximum .A universal testing machine (UTM), also known as a universal tester, [1] universal tensile machine, materials testing machine, materials test frame, is used to test the tensile strength (pulling) and compressive strength (pushing), flexural strength, bending, shear, hardness, and torsion testing, providing valuable data for designing and .TestResources is a manufacturer & provider tensile, compression, bend, fatigue testing machines and equipment for testing different materials and products. . We use this machine to perform 180° peel tests to determine the bond strength of various coatings and adhesives. It has been very reliable and problem-free, and I would recommend to .

What Is the General Procedure for Bend Testing? Equipment for Testing Tensile Bend Strength of Steel (ASTM A370), Flexural Toughness of Fiber-Reinforced Concrete (ASTM C1018), Flexural Toughness of Ceramics (ASTM C1161), and Equibiaxial Flexural Ceramics (ASTM C1499), and Flexural Testing of Glass (ASTM C158)

pittsburgh digital mini moisture meter manual

welding guided bend test equipment

2,700 likes, 29 comments - meg_vicious_1.0 on March 10, 2022: "Modo furry #parati #argentina #tiktok #reels #foryou #cosplay"

bend-strength-test-machine|guided bend tests